|

||

Designed for maximum power transmission and maintenance-free operation:

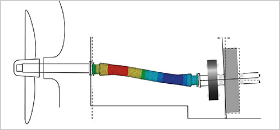

Flexshaft Drive Shafts for Ship Propulsion

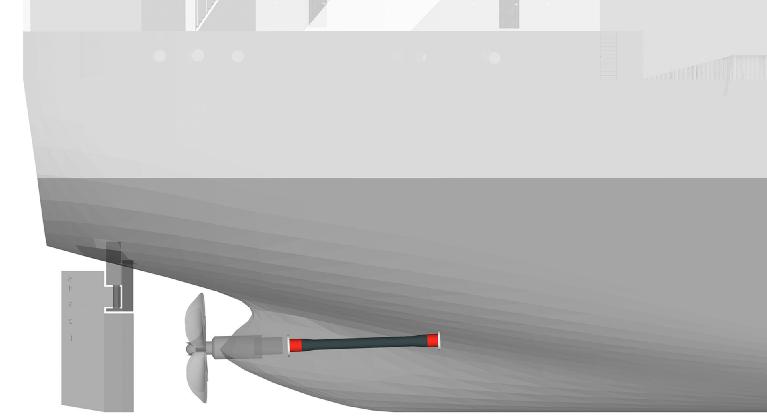

Naval vessel power train systems are constantly exposed to varying loads. The flexshaft torque shaft is specifically designed to meet the unique requirements related to the load transmission and vibration dynamics in ships.

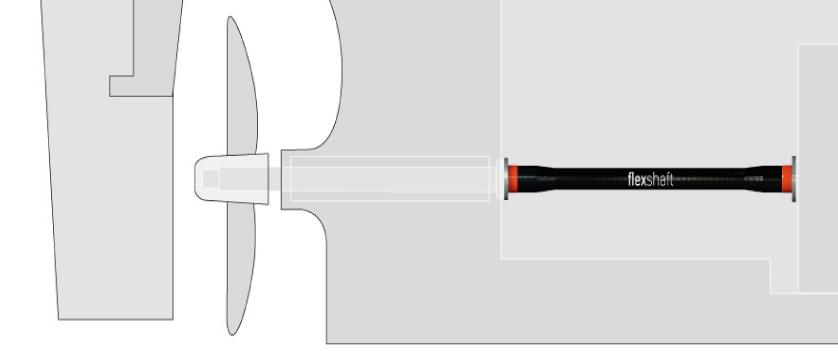

It enables direct torque transmission from the engine to the propeller and allows for a continuous transmission of torque up to 10,000 kNm. Its low bending stiffness means the flexshaft can compensate angle misalignments and axial displacements, serving as a flexible coupling. This reduces the need for moveable parts that frequently require maintenance, thus dramatically reducing system complexity and mechanical servicing requirements.

Thanks to its low density and the resulting high specific stiffness of the CFRP material, flexshaft drive shafts allow for a much longer span distance of up to 13,000 mm, significantly reducing the number of intermediate bearings to support the shaft. As a result, there is significant potential to reduce investments in expensive bearings and supporting elements.

|

||

|

|

|

||||

Highly functional drive shafts for reliable and maintenance-free operation on the high seas

The flexshaft is ideal for the specific load requirements of a drive shaft in continuous operation between the ship’s engine and the propeller. Its outstanding damping performance ensures propulsion at low-noise and low-vibration levels. Handling and transport are also much easier thanks to the much lighter construction compared to drive shafts made of steel. And thanks to absolutely maintenance-free operation throughout its complete service life, the flexshaft significantly contributes to sea freight profitability.

High Torque Strength Double tapered design ensures reliable load transfer from the carbon fibre shaft to the connection flange.

Low Bending Stiffness to compensate axial and angle displacements

10,000 kNm

13,000 mm

1,500 mm

CFRP

Tailor-made Torsional Stiffness for best balance between strength and damping

Max torque ..............................

Max length ...............................

Max diameter .............................

Material ............................................

In naval power transmissions equipped with flexshaft drive shafts, expensive and high-maintenance intermediate bearings can be omitted.

Because of their low weight, handling and replacement of flexshaft drives are carried out much easier.

High bending flexibility can balance angle and axial misalignments; shown here, an angle displacement of 2 rad*10e-3 and an axial offset of 17 mm.

larger spans

thanks to higher specific stiffness

low upfront investment

due to reduced design complexities and simplified layouts

less assembly effort

by avoiding extraneous mechanical components

significantly reduced weight

for faster, simplified handling

outstanding damping

for low noise and low vibration operation

maintenance-free

over the complete service life thanks to corrosion resistance and bearing-reduced design

high operational reliability

on account of a fully integrated in situ manufacturing process and significantly improved fatigue strength

low energy consumption

due to low inertia torque

Features and benefits at a glance