|

||

Lightweight roll systems

End-to-end solutions for demanding web processing

Groundbreaking roll cores made of fibre-reinforced composites

One way to significantly improve profitability in the production of paper, films and foils, printed materials, metals and fabrics is to raise operating speeds and user broader web widths.

:CCOR roll systems are based on a fibre-reinforced composite construction, opening the door to new roll design possibilities that are not even feasible with traditional metal-based systems. The :CCOR concept draws on a treasure trove of technical know-how, a detailed understanding of the technology and potential offered by fibre-reinforced materials, a wealth of experience in mechanical engineering and design, total familiarity with technical applications and comprehensive knowledge of functional surfaces – all culminating in end-to-end roll systems whose runnability and performance can be optimised to match the specific application.

Benefits of the advanced composites technology.

:CCOR rolls exploit the many advantages and benefits of the lightweight construction materials GFRP and CFRP: high specific stiffness, outstanding dynamic properties and a low thermal expansion coefficient – offering plenty of new design options for high-performance, fast-running roll bodies.

High specific stiffness spells higher critical speeds and less vibration. As a result, :CCOR rolls can run significantly faster than conventional rolls of the same circumference. In addition to this, wider web widths are possible while retaining the same roll diameters.

Other advantages include shorter machine run-in periods and smoother running. Because of the significantly lower weight of :CCOR rolls, it is possible to reduce drive power and thus raise energy efficiency.

Lower loads placed on bearings and roll journals mean the system is less prone to wear so mechanical components last longer. This also opens up new options for designing mountings and machine peripherals. And since the overall system is lighter, handling the roll bodies becomes quick and easy for servicing and maintenance.

Thanks to the innovative, often completely integrated journal and head design, :CCOR rolls deliver sustainably efficient force transmission, improved safety tolerances and ultimate reliability.

Features and benefits at a glance

significantly reduced weight

compared to steel rolls

high energy efficiency

thanks to reduced drive power

lower upfront investment

due to the use of lighter drives, bearings and journals

easy handling

during installation and maintenance

thermal stability

thanks to a low thermal expansion coefficient

fast startup

thanks to reduced run-in period

wider web widths and faster machine operation

at the same diameters

high operational reliability

thanks to fully integrated manufacturing process

Application areas

Paper Industry

Film&Foil Industry

Printing Industry

Textile Industry

Non-Woven-Industry

Metal Industry

|

||

|

|

|

|

|

|

|

||

Application areas

Paper Industry

Film&Foil Industry

Printing Industry

Textile Industry

Non-Woven-Industry

Metal Industry

light

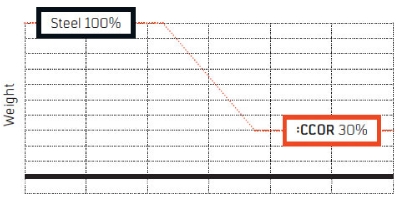

Weight comparison:

Mass reduction of up to 70% compared to a steel roll of the same size.

stiff

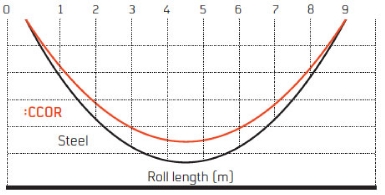

:CCOR rolls offer low deflection under own weight, with minimal radial displacement even with higher web width.

fast

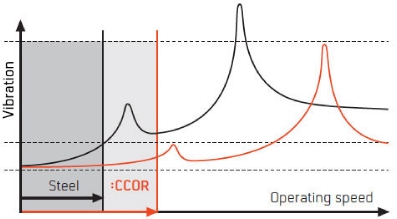

Increase in the critical speed compared to steel.

:CCOR rolls can operate at much higher speeds than conventional rolls of the same dimensions.

Covers and coatings

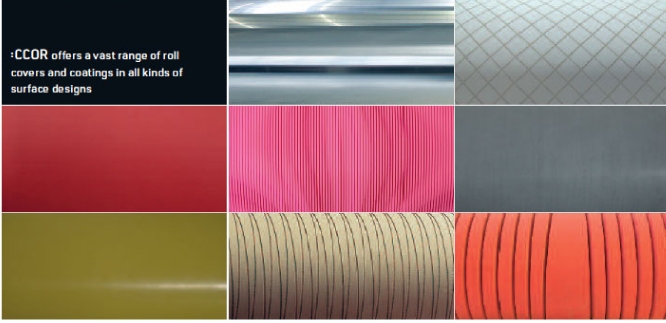

Functional coatings not only enhance the overall performance of roll systems, they also extend the range of applications for which the rolls can be used. Indeed they often play a pivotal role in improving the quality of the finished product. For example, typical requirements include scratch resistance, wear and corrosion protection, chemical resistance or non-stick properties.

Roll surface profiles such as grooving, diamond or spiral patterns play an essential part in the manufacturing process of the end product.

Sophisticated roll surface coatings of all kinds of polymer, metal, tungsten carbide and ceramic materials make :CCOR roll systems a complete solution for the most demanding web processing applications.

Polymer covers: rubber, polyurethane, thermoset

Ceramic and hard metal coatings: aluminium oxide, chromium oxide, tungsten carbides

Steel and metal shells: stainless steel, aluminium, copper